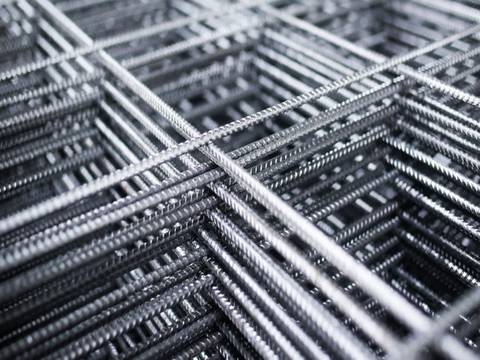

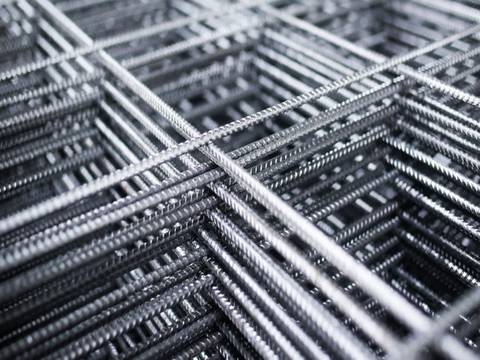

RM-04: Galvanized reinforcing mesh.

Reinforcing Mesh is used for the reinforcement of concrete, is manufactured to SANS 1024:2006 and to other international standard specifications.

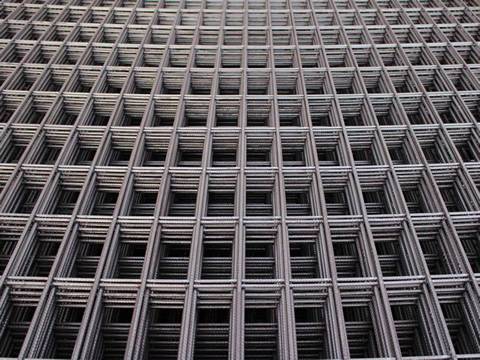

RM-01: Reinforcing mesh sheets

In order to obtain the best results when using fabric reinforcement, special care must be taken to ensure that the mesh is positioned and maintained at the correct depth after the concrete pour. This can be done by using stools or plastic or concrete spacers. Another option is to place the fabric on poured concrete that has been leveled to the desired reinforcement depth. After placing the mesh the concrete can be topped up to the specified overall slab thickness.

Ideally fabric must be located 50 mm from the top of the slab and where bottom steel is required, it must also be supported 50 mm above the substrate.

RM-02: Reinforcing mesh in rolls

It is recommended that in calculating the lap requirement for surface bed welded mesh fabric reinforcement that the formula shall be 25 × diameter + 150 mm or 300 mm, whichever is the greatest.

The Reinforcing Mesh is manufactured under strict quality controls with all standards conforming to SANS 1024:2006 standard specifications and tolerances and carries the certification mark.

RM-02: Reinforcing mesh in rolls

RM-04: Galvanized reinforcing mesh.

RM-05: Reinforcing mesh with uniform square holes.

RM-06: Reinforcing mesh is packed with metal belt.

RM-07: Reinforcing mesh is placed on wooden pallet in workshop.

| Products | Fabric | Mesh Size Nominal Pitch of Wire | Wire Sizes | Cross Sectional area/m width | Nominal mass/m2 | Package | |||

|---|---|---|---|---|---|---|---|---|---|

| Ref No. | Main mm | Cross mm | Main mm | Cross mm | Main mm | Cross mm | Kg | Supplied in | |

| Square Mesh Fabric | 888 | 200 | 200 | 12 | 12 | 566 | 566 | 8.88 | sheets only 6 m × 2.4 m |

| 746 | 200 | 200 | 11 | 11 | 475 | 475 | 7.46 | ||

| 617 | 200 | 200 | 10 | 10 | 393 | 393 | 6.17 | ||

| 500 | 200 | 200 | 9 | 9 | 318 | 318 | 5.00 | ||

| 395 | 200 | 200 | 8 | 8 | 251 | 251 | 3.95 | ||

| 311 | 200 | 200 | 7.1 | 7.1 | 198 | 198 | 3.11 | ||

| 245 | 200 | 200 | 6.3 | 6.3 | 156 | 156 | 2.45 | ||

| 193 | 200 | 200 | 5.6 | 5.6 | 123 | 123 | 1.93 | sheets or rolls | |

| 100 | 200 | 200 | 4 | 4 | 63 | 63 | 1.00 | ||

| Design Mesh Fabric | 1085 | 100 | 200 | 12 | 8 | 1131 | 251 | 10.85 | sheets only 6 m × 2.4 m |

| 943 | 100 | 200 | 11 | 8 | 951 | 251 | 9.43 | ||

| 772 | 100 | 200 | 10 | 7.1 | 786 | 198 | 7.72 | ||

| 655 | 100 | 200 | 9 | 7.1 | 636 | 198 | 6.55 | ||

| 517 | 100 | 200 | 8 | 6.3 | 503 | 156 | 5.17 | ||

| 433 | 100 | 200 | 7.1 | 6.3 | 396 | 156 | 4.33 | ||

| 341 | 100 | 200 | 6.3 | 5.6 | 312 | 123 | 3.41 | ||

| 289 | 100 | 200 | 5.6 | 5.6 | 246 | 123 | 2.89 | ||

| Longitudinal Mesh Fabric | 278 | 100 | 300 | 6.3 | 4 | 312 | 42 | 2.78 | sheets only 6 m × 2.4 m |

| 226 | 100 | 300 | 5.6 | 4 | 246 | 42 | 2.26 | ||

| 133 | 100 | 300 | 4 | 4 | 126 | 42 | 1.33 | sheets or rolls 60 m × 2.4 m |

|

| Special Mesh | 200 | 100 | 100 | 4 | 4 | 126 | 126 | 2.00 | |

| 156 | 100 | 100 | 3.55 | 3.55 | 99 | 99 | 1.56 | ||

| DIA mm |

Area mm2 |

Mass kg/m |

Wire Spacing mm | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | DIA | |||

| 12 | 113.11 | 2262 | 1508 | 1131 | 905 | 754 | 646 | 566 | 503 | 452 | 411 | 377 | 12 | |

| 0.888 | 17.76 | 11.84 | 8.88 | 7.1 | 5.92 | 5.07 | 4.44 | 3.95 | 3.55 | 3.23 | 2.96 | |||

| 11 | 95.05 | 1901 | 1267 | 950 | 760 | 634 | 583 | 475 | 422 | 380 | 346 | 317 | 11 | |

| 0.746 | 14.92 | 9.95 | 7.46 | 5.97 | 4.97 | 4.26 | 3.73 | 3.32 | 2.98 | 2.71 | 2.49 | |||

| 10 | 78.55 | 1571 | 1047 | 786 | 628 | 524 | 449 | 393 | 349 | 314 | 286 | 262 | 10 | |

| 0.617 | 12.34 | 8.23 | 6.17 | 4.94 | 4.11 | 3.53 | 3.09 | 2.74 | 2.47 | 2.24 | 2.06 | |||

| 9 | 63.63 | 1273 | 848 | 636 | 509 | 424 | 364 | 318 | 283 | 255 | 231 | 212 | 9 | |

| 0.500 | 9.99 | 6.67 | 4.99 | 3.99 | 3.33 | 2.86 | 2.5 | 2.22 | 2.00 | 1.82 | 1.67 | |||

| 8 | 50.27 | 1005 | 670 | 503 | 402 | 335 | 287 | 251 | 223 | 201 | 183 | 168 | 8 | |

| 0.395 | 7.9 | 5.27 | 3.95 | 3.16 | 2.63 | 2.26 | 1.98 | 1.76 | 1.58 | 1.44 | 1.32 | |||

| 7.1 | 39.6 | 792 | 528 | 396 | 317 | 264 | 226 | 198 | 176 | 158 | 144 | 132 | 7.1 | |

| 0.311 | 6.22 | 4.15 | 3.11 | 2.49 | 2.07 | 1.78 | 1.56 | 1.38 | 1.24 | 1.13 | 1.04 | |||

| 6.3 | 31.18 | 624 | 416 | 312 | 249 | 208 | 178 | 156 | 139 | 125 | 113 | 104 | 6.3 | |

| 0.245 | 4.9 | 3.27 | 2.45 | 1.96 | 1.63 | 1.40 | 1.23 | 1.09 | 0.98 | 0.89 | 0.82 | |||

| 5.6 | 24.63 | 493 | 328 | 246 | 197 | 164 | 141 | 123 | 109 | 99 | 90 | 82 | 5.6 | |

| 0.193 | 3.86 | 2.57 | 1.93 | 1.54 | 1.29 | 1.11 | 0.97 | 0.86 | 0.78 | 0.71 | 0.64 | |||

| 4 | 12.57 | 251 | 168 | 126 | 101 | 84 | 72 | 63 | 56 | 50 | 46 | 42 | 4 | |

| 0.099 | 1.98 | 1.33 | 1 | 0.8 | 0.67 | 0.57 | 0.5 | 0.44 | 0.4 | 0.36 | 0.33 | |||